Shopping for a hydraulic piston cylinder from China? You’ve probably noticed prices swinging wildly from as low as $50 to over $5,000—a jaw-dropping 300% difference! It’s enough to make anyone scratch their head, wondering if they’re getting ripped off or buying junk. Pick the wrong cylinder, and you’re stuck with equipment breakdowns, skyrocketing repair costs, or even safety risks. Overpay, and your budget takes an unnecessary hit. Don’t worry—we’ve got you covered. This article dives deep into why Chinese hydraulic cylinder prices vary so much and gives you the insider scoop to snag the best deal without compromising quality.

The global hydraulic cylinder market was valued at $15 billion in 2023 and is projected to grow at a 4.6% CAGR, with China as a key player (Global Market Insights). But with such a wide price range, understanding the factors behind these costs is crucial to making a smart purchase.

What Drives Hydraulic Piston Cylinder Price Differences?

Let’s break down the key reasons behind the massive price gaps in hydraulic cylinder pistons from China. Knowing these will help you avoid low-quality traps or overpriced products.

1. Hydraulic Cylinder Type and Design

Not all hydraulic cylinders are created equal. Different types—like tie-rod, welded, or telescopic—come with varying manufacturing complexities and costs.

- Tie-Rod Cylinders: Common in agriculture and light industry, these are simpler to produce, making them budget-friendly.

- Welded Cylinders: Built for heavy-duty tasks like construction equipment, they’re sturdier and pricier due to robust construction.

- Telescopic Cylinders: Used in compact spaces needing long strokes (think dump trucks), their complex design drives up costs.

For example, a small tie-rod cylinder for farm machinery might cost as little as $50, while a heavy-duty telescopic cylinder can run into thousands (Made-in-China.com).

2. Hydraulic Cylinder Size and Specifications

The physical size and performance specs of a hydraulic cylinder and piston heavily influence its price.

- Bore Size: Larger bores require more material and intricate machining, increasing costs.

- Stroke Length: Longer strokes mean longer rods and barrels, adding to material and production expenses.

- Pressure Rating: Cylinders designed for higher pressures need stronger materials and tighter tolerances, pushing prices up.

A small cylinder with a 1-inch bore and 4-inch stroke might cost around $50, while an 8-inch bore with a 60-inch stroke could hit $5,000 or more (Made-in-China.com).

3. Material Quality in Hydraulic Cylinders

The materials used in a hydraulic cylinder directly impact its performance and price.

- Standard Steel: Used in general applications, it’s cost-effective for budget-conscious buyers.

- High-Grade Steel or Alloys: Ideal for high-pressure or corrosive environments (like marine applications), these materials significantly raise costs.

- Seals and Components: Premium hydraulic cylinder piston seals (e.g., fluorocarbon) are more durable but pricier than standard options.

For instance, a Chinese company developed a massive hydraulic cylinder for offshore pile driving using specialized alloys to withstand harsh conditions, making it far costlier than standard models (Interesting Engineering).

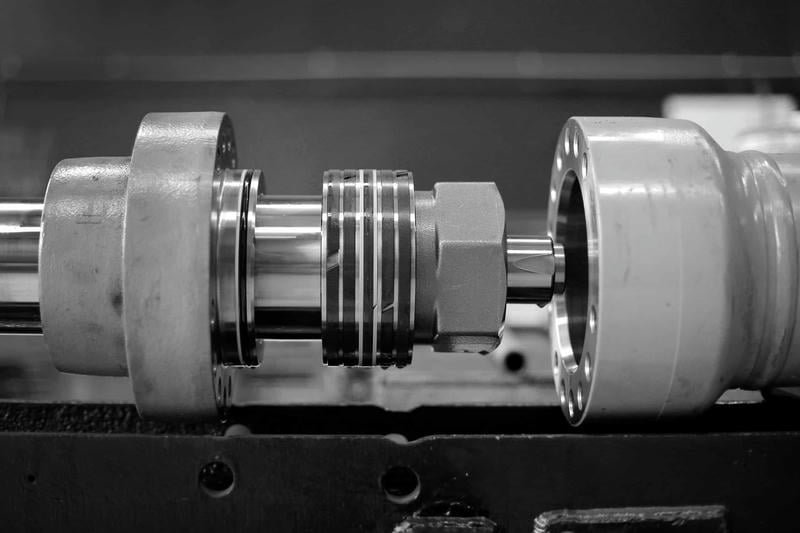

4. Manufacturing Precision

The level of precision in manufacturing affects both performance and cost.

- Tolerance Levels: Tighter tolerances ensure smoother operation and longer life but require advanced machinery and skilled labor.

- Surface Finish: High-quality surface treatments on hydraulic cylinder piston rods and barrels reduce wear, extending lifespan but adding to production costs.

High-precision manufacturing is often associated with premium brands that invest in quality control for consistent performance.

5. Brand Reputation and Reliability

Well-known brands charge a premium for their proven quality and reliability.

- Quality Assurance: Reputable manufacturers like Hengli Hydraulic implement strict quality control, ensuring consistent performance.

- After-Sales Support: Longer warranties and better technical support justify higher prices.

China’s market includes both big players like Hengli and smaller, lesser-known suppliers. The latter may offer lower prices, but quality can be hit-or-miss. Hengli, for example, is praised for its innovation and reliability (Interesting Engineering).

6. Certifications and Standards Compliance

Cylinders meeting international standards or specific certifications come with higher price tags.

- ISO Standards: Compliance with ISO 9001 signals a commitment to quality manufacturing.

- Industry-Specific Certifications: Cylinders for marine applications may require DNV or ABS certifications, adding to costs.

These certifications ensure rigorous safety and performance standards but increase production expenses.

7. Customization Options

Custom hydraulic cylinder parts tailored to specific applications cost more than standard models.

- Special Features: Unique mounting options, integrated sensors, or corrosion-resistant coatings drive up prices.

- Small-Batch Production: Custom orders often involve limited runs, lacking the economies of scale of mass production.

Custom telescopic cylinders, for instance, can cost several times more than off-the-shelf models (Made-in-China.com).

8. Production Volume and Economies of Scale

Manufacturers producing standard cylinders in large volumes can offer lower prices due to economies of scale.

- Mass Production: Streamlined processes reduce per-unit costs, ideal for buyers needing standard cylinders.

- Small-Batch Production: Niche or custom products have higher production costs, leading to pricier cylinders.

Large suppliers might offer tie-rod cylinders at lower prices, while smaller manufacturers charge more for custom units.

Balancing Quality and Cost When Buying Hydraulic Cylinders

When sourcing hydraulic cylinders for sale, striking a balance between quality and cost is key. Here’s what to look for:

- Define Your Needs: Specify load capacity, stroke length, operating speed, and environmental conditions (e.g., temperature or corrosion). This prevents overpaying for unnecessary features.

- Research Supplier Reputation: Look for manufacturers with strong reviews, certifications, and transparent processes. Hengli Hydraulic, for example, is lauded for reliability and innovation (Interesting Engineering).

- Verify Product Quality: Request samples or test reports if possible. Visiting factories can also provide insight into manufacturing standards.

- Consider Total Cost of Ownership: Cheap cylinders may save money upfront but can lead to frequent repairs and downtime if quality is poor. As construction equipment manager John shared, “We bought cheap cylinders to cut costs, but they kept failing, causing delays and extra expenses. Switching to a reputable brand made our operations much smoother.”

How to Get the Best Deal on Hydraulic Piston Cylinders

To secure high-quality hydraulic piston cylinder price at a fair price, follow these practical tips:

- Clarify Specifications: Know the exact bore size, stroke length, and pressure rating you need to avoid overspending on overbuilt products.

- Compare Multiple Suppliers: Get quotes from several manufacturers, weighing price, quality, and delivery times. Platforms like Made-in-China.com offer extensive supplier lists for easy comparison.

- Ask About Bulk Discounts: If you need multiple cylinders, inquire about discounts for bulk purchases to lower per-unit costs.

- Verify Certifications and Reviews: Ensure suppliers have certifications like ISO 9001 and check customer reviews for reliability insights.

- Negotiate Terms: Haggle on price, delivery timelines, and payment terms to secure a better deal.

By taking these steps, you can source top-notch hydraulic piston cylinders from China while staying within budget.

Make Smart Choices for Your Hydraulic Cylinders

The 300% price variation in Chinese hydraulic piston cylinders comes down to factors like cylinder type, size, materials, manufacturing precision, brand reputation, certifications, customization, and production volume. Understanding these drivers empowers you to choose a cylinder that meets your performance needs without breaking the bank.

While bargain cylinders might seem tempting, poor quality can lead to costly repairs and downtime. Instead, opt for reputable suppliers and ensure the cylinder matches your specific requirements for the best balance of performance and cost.

Ready to find high-quality hydraulic piston cylinders? Contact us for a quote or expert guidance. Your equipment deserves the best!

What’s the biggest challenge you face when sourcing hydraulic cylinders? Drop your thoughts below, and let’s tackle it together!

Leave a Reply