When a hydraulic cylinder piston fails, it can bring your entire operation to a screeching halt—costing you time, money, and maybe even a few choice words. For businesses in the global hydraulic cylinder market, choosing the right piston material is a make-or-break decision. This report dives into the failure rates of hydraulic cylinder pistons based on material type, offering insights to help you select the best option for your hydraulic systems. Whether you’re sourcing hydraulic cylinders or pistons, we’ve got you covered with data-driven recommendations.

Why Hydraulic Piston Material Matters

Imagine your hydraulic system as the heart of your machinery. The piston is the pulse, driving every movement. A failure here doesn’t just slow you down—it can lead to catastrophic downtime. Our experience with clients in industries like manufacturing and construction shows that material choice directly impacts reliability. According to a 2023 study by Dura-Bar, material selection can reduce failure rates by up to 25% in high-stress applications (Dura-Bar Case Study).

Common Hydraulic Piston Materials

Hydraulic pistons are typically made from:

- Cast Iron: Known for its wear resistance and affordability, cast iron is a go-to for standard hydraulic piston cylinders (Cast Iron for Pistons).

- Steel: Offers high strength and durability, ideal for high-pressure environments like heavy machinery (Materials for Hydraulic Actuators).

- Aluminum: Lightweight but less durable, used in applications where weight is a priority (Material Selection).

- POM (Polyoxymethylene): A lightweight, corrosion-resistant plastic for low-pressure systems, but it’s not built for heavy loads.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Key Applications |

|---|---|---|---|---|---|

| Cast Iron 65-45-12 | 7.1 | 448 | 310 | 131–220 | Standard hydraulic cylinders |

| C45 Steel | 7.8 | 580 | 305 | 200 | High-pressure, heavy-duty |

| Aluminum 7075-T6 | 2.8 | 510 | 430 | 150 | Lightweight applications |

| POM | 1.41 | 67–85 | 67–69 | 81 Shore D | Low-pressure, corrosion-resistant |

Key Factors Driving Hydraulic Piston Failures

Let’s face it—pistons don’t fail because they’re having a bad day. Several factors conspire to push them to the breaking point:

- Operating Pressure: High pressure can cause material fatigue or cracking. Steel shines here, while POM struggles.

- Temperature Extremes: Hot or cold environments can cause expansion or contraction, leading to leaks or mechanical issues.

- Fluid Compatibility: Incompatible hydraulic fluids can corrode pistons, spiking failure rates.

- Wear and Tear: Over time, surface wear chips away at performance. Cast iron’s durability helps it hold up longer.

Think of your piston like a marathon runner: the wrong shoes (material) or a brutal course (environment) can lead to a breakdown.

Hydraulic Piston Failure Rates by Material

Exact failure rates are tough to pin down—they vary by application—but industry trends give us a clear picture:

- Cast Iron: Moderate failure rates in standard applications. Its wear resistance makes it reliable, but it can crack under impact loads.

- Steel: Low failure rates in high-pressure settings due to its strength and fatigue resistance. Perfect for heavy-duty hydraulic cylinder and piston systems.

- Aluminum: Higher failure rates due to wear and lower durability. Best for low-load, lightweight systems.

- POM: High failure rates in anything beyond low-pressure applications. It’s simply not built for stress.

A real-world example? A manufacturing plant switched from cast iron to steel pistons and saw a 25% drop in failures, slashing downtime and maintenance costs (Dura-Bar Case Study).

A Customer’s Story: Real Results

“We were tearing our hair out over constant hydraulic cylinder failures,” says John, an engineer at a Midwest manufacturing facility. “Our cast iron pistons kept giving out under heavy loads. Switching to steel pistons cut our failure rate by 25% and saved us thousands in downtime. It was a game-changer.” John’s story isn’t unique—material upgrades can transform your operation.

How to Choose the Right Hydraulic Piston Material

Ready to make a smart choice? Here’s your playbook:

- Assess Your Application: What’s the pressure, load, and environment? High-pressure systems need steel; standard ones can use cast iron.

- Match Material to Needs: Cast iron for cost-effective durability, steel for heavy-duty performance, aluminum for lightweight designs, or POM for low-pressure corrosion resistance.

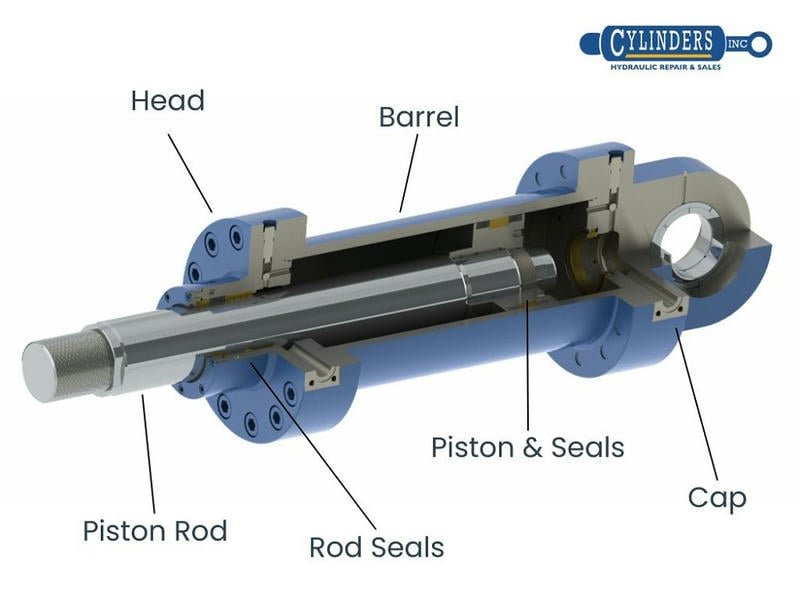

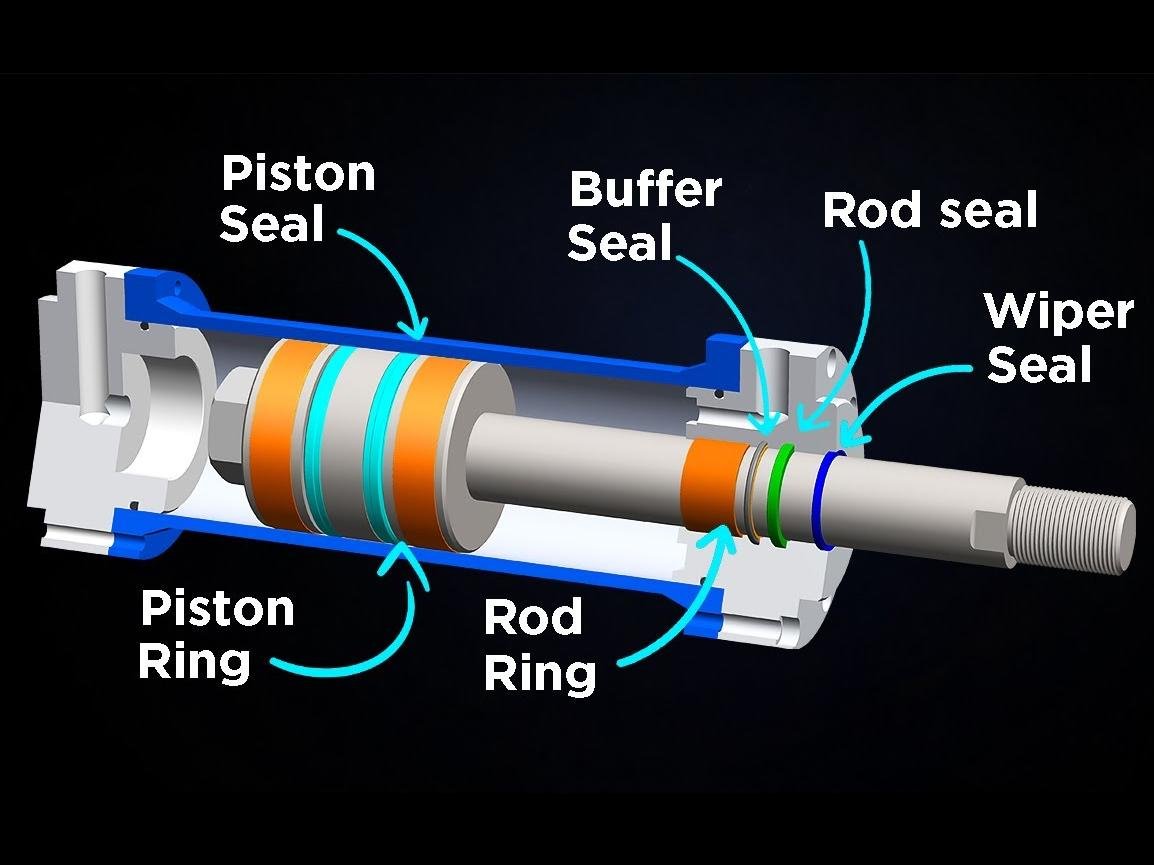

- Prioritize Maintenance: Regular checks for wear, proper hydraulic cylinder piston seals, and clean hydraulic fluid can extend piston life.

- Follow Standards: Stick to ISO 6020/6022 guidelines for material and design to ensure reliability (ISO Standards).

By aligning material choice with your specific needs, you’ll keep your hydraulic cylinders humming and your downtime minimal.

Your Path to Reliable Hydraulic Systems

Choosing the right hydraulic piston material isn’t just about avoiding failures—it’s about building a system you can trust. Cast iron offers dependable performance for everyday applications, steel tackles the toughest jobs, aluminum keeps things light, and POM handles low-pressure tasks. Combine smart material selection with proactive maintenance, including timely hydraulic cylinder repair, and you’ll have a hydraulic system that’s built to last.

Got a question about your hydraulic cylinder pistons? Drop a comment below or reach out to explore our range of high-quality hydraulic cylinder parts. Let’s keep your operation running smoothly.

Leave a Reply