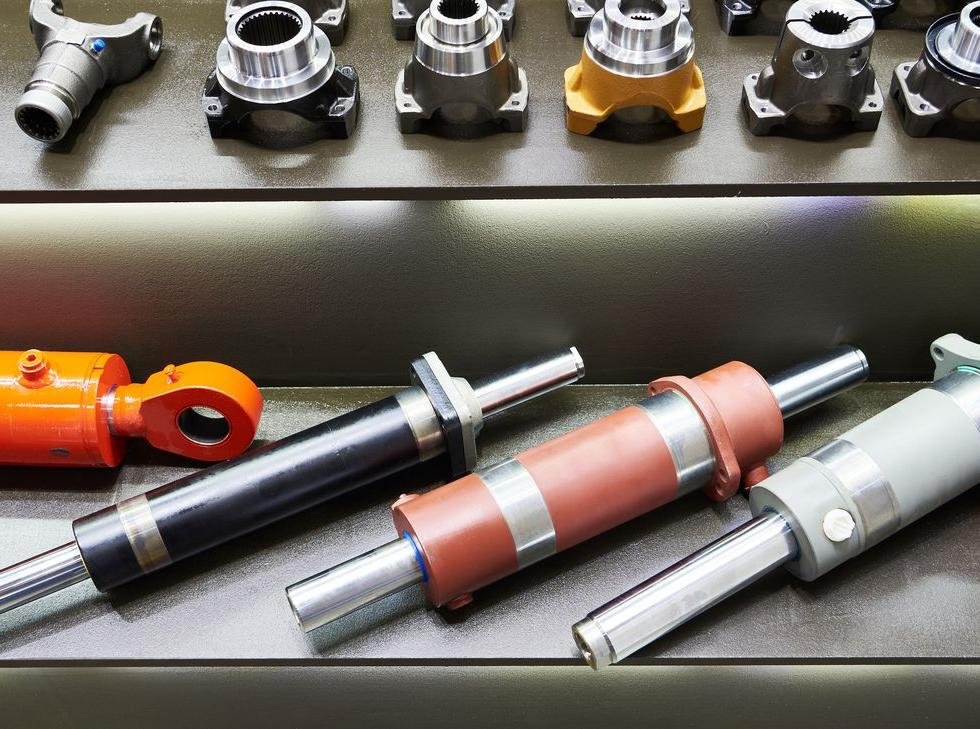

Maintaining hydraulic systems often involves disassembling hydraulic cylinders, a task that demands precision and care. Even seasoned technicians can make mistakes that lead to costly repairs, extended downtime, or safety hazards. This article highlights five common mistakes to avoid when using a hydraulic cylinder piston removal tool and provides a safety checklist to ensure you get the job done right—safely and efficiently.

Mistake 1: Failing to Release System Pressure Before Disassembly

One of the most dangerous mistakes is starting disassembly without releasing hydraulic pressure in a hydraulic cylinder and piston. Hydraulic systems operate under high pressure, and failure to depressurize can cause fluid or components to erupt suddenly, leading to serious injury or equipment damage. For instance, high-pressure oil spray can cause burns or contaminate the workspace, increasing cleanup and repair costs.

Why It’s Costly

According to Cylinders, Inc., 12.6% of hydraulic cylinder failures stem from improper maintenance, including failure to depressurize. This can lead to damaged seals or cylinder failure, with repair costs potentially reaching hundreds of dollars.

How to Avoid It

Before disassembly, shut down the hydraulic system and loosen the relief valve or pressure adjustment screw to release all pressure. Use a pressure gauge to confirm the system is fully depressurized, ensuring safe operation.

Customer Testimonial

“I once forgot to depressurize, and oil sprayed everywhere—nearly got hurt. Now, I double-check the pressure every time to stay safe.” — John D., Mechanical Technician

Mistake 2: Using Incorrect or Inadequate Hydraulic Cylinder Piston Removal Tools

Using the wrong tools can damage hydraulic cylinder parts, strip threads, or cause personal injury. Each hydraulic cylinder may require specific tools, like specialized wrenches or snap ring pliers, and using improper ones can complicate disassembly and cause unnecessary wear.

Why It’s Costly

Degelman Industries notes that improper tools can lead to scratches on hydraulic cylinder piston rod surfaces or damaged threads, increasing repair costs. In severe cases, replacing an entire piston rod can significantly inflate expenses.

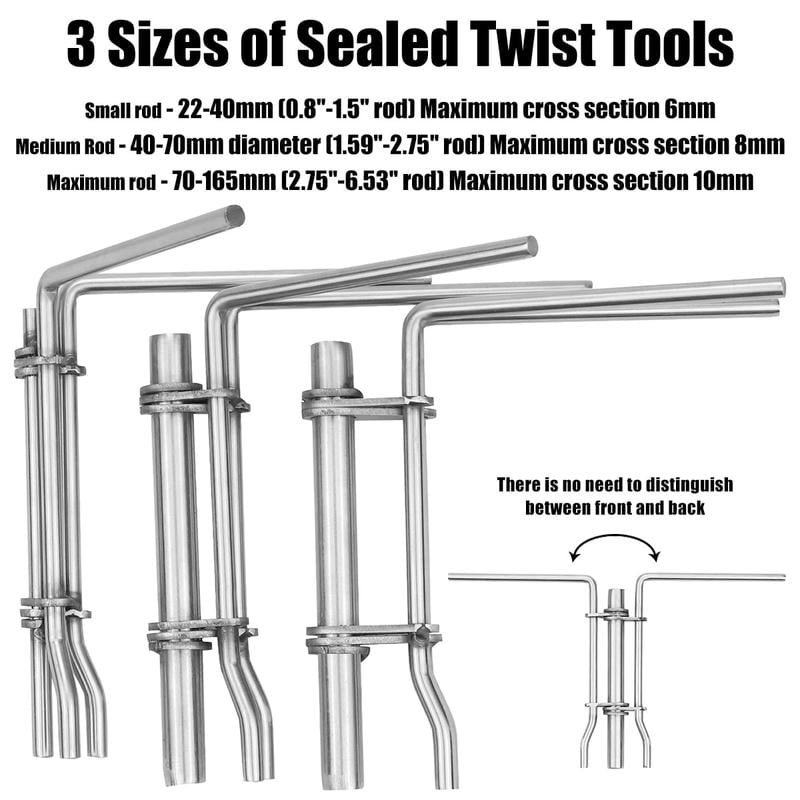

How to Avoid It

Familiarize yourself with the tools required for your specific cylinder model. Invest in high-quality tools designed for hydraulic cylinder disassembly, such as adjustable spud wrenches or hydraulic cylinder piston seal installation tool, to ensure efficiency and safety.

Mistake 3: Applying Excessive Force During Hydraulic Cylinder Piston Removal

When components are stuck due to corrosion or other issues, technicians may be tempted to apply excessive force. However, this can bend piston rods, crack components, or strip threads, making hydraulic cylinder repair more difficult and expensive.

Why It’s Costly

Flowfit reports that 25% of mechanical equipment failures stem from improper operation or maintenance. Excessive force can cause internal cylinder scratches, escalating repair costs from simple seal replacements (around $100) to full rebuilds ($500 or more).

How to Avoid It

If components are stuck, investigate the cause. Use penetrating oil, apply heat if appropriate, or consult the manufacturer’s guidelines. Avoid brute force to prevent further damage.

Mistake 4: Failing to Properly Secure the Hydraulic Cylinder

Hydraulic piston cylinders can be heavy and unwieldy. Failing to secure them properly during disassembly can cause the cylinder to shift or fall, leading to injury or damage to the cylinder and surrounding equipment.

Why It’s Costly

Wuxi Gloria Industrial Tech highlights that unbalanced cylinders can lead to bent or deformed piston rods, increasing repair complexity and costs. Additionally, workplace accidents can result in medical expenses and downtime losses.

How to Avoid It

Use proper supports, vises, or fixtures to secure the cylinder firmly. Ensure the workspace is clear, and the cylinder is positioned stably to reduce the risk of tipping or rolling.

Mistake 5: Ignoring Hydraulic Cylinder Piston Removal Instructions

Every hydraulic cylinder piston has a unique design, and manufacturers provide specific disassembly instructions. Ignoring these can lead to improper procedures, missed steps, or incorrect reassembly, causing premature failure.

Why It’s Costly

Failing to follow manufacturer instructions can result in improper hydraulic cylinder piston seals installation or component misalignment, impacting cylinder performance. Cylinders, Inc. notes that hydraulic cylinder rebuild costs vary by damage extent, but improper disassembly can turn a simple repair into a full rebuild, significantly increasing expenses.

How to Avoid It

Always refer to the manufacturer’s service manual or guidelines, following the recommended procedures step-by-step for your specific cylinder. Ensure all steps are executed correctly to guarantee successful and safe disassembly.

Hydraulic Cylinder Disassembly Safety Checklist

To ensure a safe and efficient disassembly process, follow this checklist:

- Depressurize the System: Confirm all pressure in the hydraulic system is released.

- Use Correct Tools: Select hydraulic cylinder piston removal tools suited for the specific cylinder.

- Secure the Cylinder: Properly fix the cylinder to prevent movement.

- Follow Instructions: Adhere to the manufacturer’s disassembly procedures.

- Wear Safety Gear: Use appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Maintain a Clean Environment: Keep the work area clean to prevent contamination.

- Handle Components Carefully: Avoid damaging seals, surfaces, or threads.

- Proper Fluid Disposal: Handle and dispose of hydraulic fluid per regulations.

By avoiding these common mistakes and following the safety checklist, you can ensure hydraulic cylinder disassembly is safe and effective, minimizing downtime and repair costs.

Disassembling a hydraulic cylinder requires meticulous attention and adherence to safety protocols. By understanding these five costly mistakes and following the provided safety checklist, you can protect yourself, your equipment, and your bottom line. For more information on hydraulic cylinder maintenance or to explore our high-quality hydraulic cylinders for sale, visit our website or contact us today.

Leave a Reply