Imagine your production line grinding to a halt because a hydraulic cylinder piston fails. The culprit? A tiny scratch on the piston rod that went unnoticed. According to a 2021 MDPI study, over 41% of hydraulic cylinder failures stem from fluid contamination, and 12.6% from improper maintenance. These preventable errors cost businesses millions in downtime and repairs.

In this article, we uncover three mistakes nearly every operator makes when maintaining hydraulic cylinder pistons and share practical tips to keep your equipment running smoothly. Whether you’re managing heavy machinery or sourcing reliable components, avoiding these pitfalls can save you time, money, and headaches.

Mistake 1: Overlooking Piston Rod Inspection in Hydraulic Cylinder Piston Maintenance

The hydraulic cylinder piston rod is the workhorse of your hydraulic cylinder, transmitting force to move heavy loads. Yet, it’s often exposed to harsh conditions, making it prone to scratches, dents, or corrosion. Many operators skip regular rod inspections, assuming “it looks fine.” This oversight can spell disaster.

Why It’s a Problem

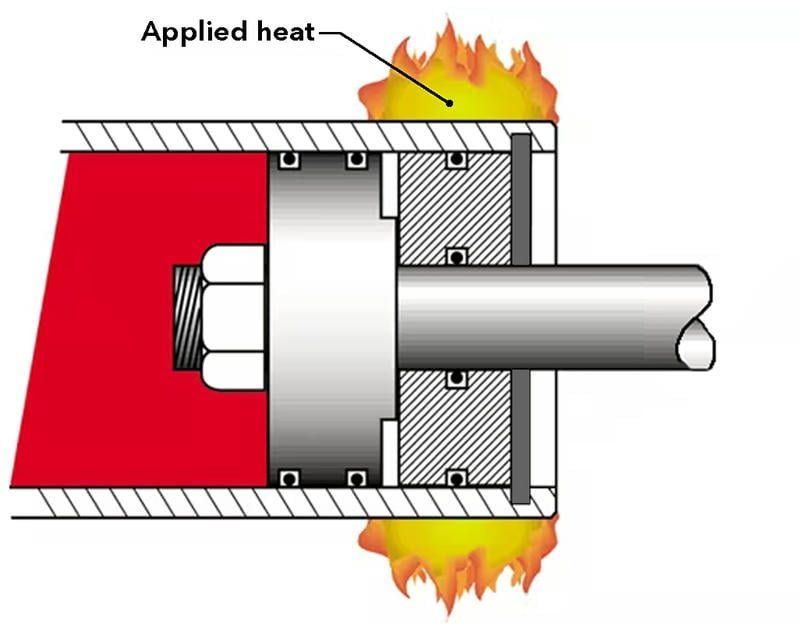

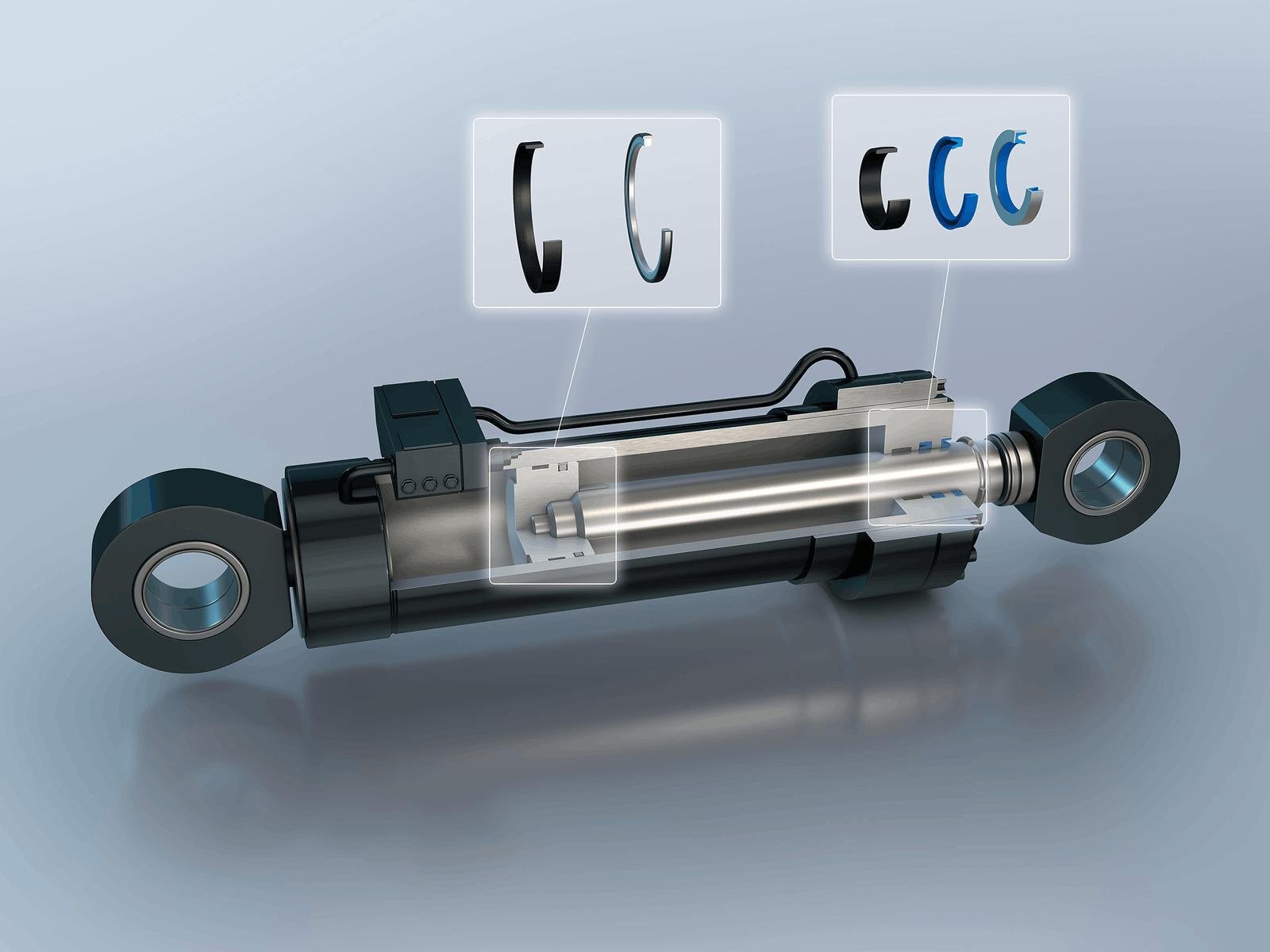

A scratched or corroded piston rod can tear hydraulic cylinder piston seals, causing hydraulic fluid leaks. Leaks reduce efficiency, increase wear, and may lead to catastrophic failure. Cylinders Inc. notes that damaged seals, often caused by rod scratches, are a leading cause of cylinder breakdowns.

How to Fix It

- Inspect Regularly: Check the rod for scratches, dents, or rust at least monthly. Use a flashlight to spot subtle damage.

- Clean Thoroughly: Wipe the rod with a clean cloth to remove dirt and moisture after each use.

- Protect When Idle: Use rod boots or covers during storage to shield against environmental damage.

- Act Fast: Polish minor scratches or replace the rod if damage is severe.

Case Study: A Midwest construction firm faced frequent cylinder failures on their excavators. After discovering scratched piston rods were damaging seals, they implemented weekly rod inspections and cleaning. Within three months, downtime dropped by 50%, saving thousands in hydraulic cylinder repair.

Mistake 2: Ignoring Fluid Cleanliness in Hydraulic Cylinder Piston Care

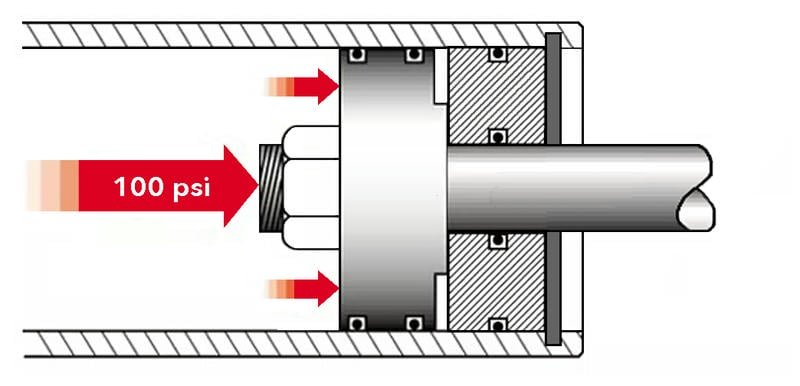

Hydraulic fluid is the lifeblood of your hydraulic cylinder and piston, but contaminated fluid is like poison. Dirt, water, or metal particles can wreak havoc on the piston and seals, yet many operators neglect fluid maintenance.

Why It’s a Problem

Contaminated fluid abrades the piston and cylinder walls, leading to leaks and reduced performance. The MDPI study highlights that fluid contamination causes 41.1% of cylinder failures, making it the top issue. Aurelius Manufacturing warns that dirty fluid can also clog valves, disrupting the entire system.

How to Fix It

- Change Fluid Regularly: Follow manufacturer guidelines, typically every 1,000 hours or annually.

- Use Quality Filters: Install high-grade filters and replace them as recommended.

- Handle with Care: Use clean containers when adding fluid to avoid introducing contaminants.

- Test Fluid: Periodically analyze fluid for contamination using a testing kit.

Testimonial: “We used to replace cylinders every year due to leaks. After switching to a strict fluid maintenance schedule, our cylinders last twice as long. It’s a game-changer!” — Sarah T., Operations Manager, Pacific Industrial.

Mistake 3: Neglecting Alignment to Prevent Hydraulic Cylinder Piston Failure

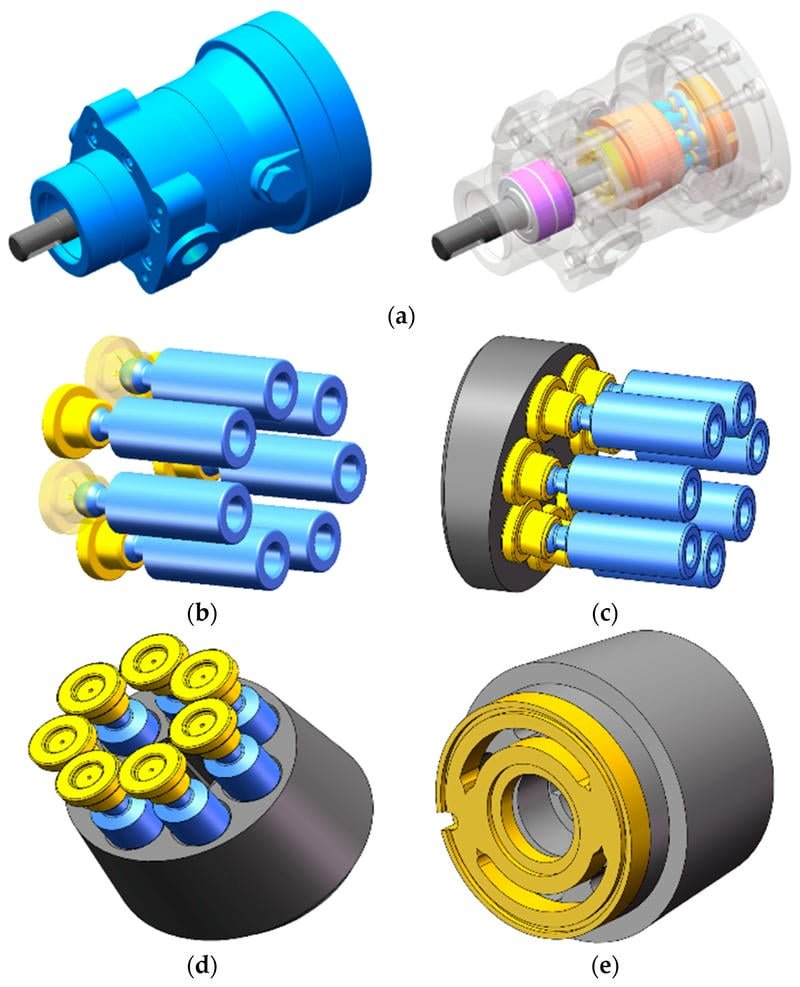

Proper alignment ensures your hydraulic piston cylinder operates efficiently, but misalignment or side loading is a silent killer. Many operators assume their setup is fine, only to face premature piston wear.

Why It’s a Problem

Side loading—when force is applied off the cylinder’s axis—causes uneven piston wear, seal damage, and rod bending. RHK Hydraulics reports that side loading can lead to hazardous rod breaks, risking equipment and safety.

How to Fix It

- Align During Installation: Use laser alignment tools to ensure the cylinder is perfectly positioned.

- Check Mountings: Inspect mounts for wear or looseness that could cause misalignment.

- Monitor Operation: Listen for unusual noises or vibrations, which may indicate side loading.

- Stay Within Limits: Avoid exceeding the cylinder’s load capacity to prevent stress.

Case Study: A mining company in Australia noticed their hydraulic cylinders failed every six months. An audit revealed side loading due to misaligned mounts. After realigning and upgrading to trunnion mounts, cylinder lifespan doubled, boosting productivity.

Your Next Steps for Reliable Hydraulic Cylinder Piston Maintenance

Avoiding these three mistakes—overlooking piston rod inspection, ignoring fluid cleanliness, and neglecting alignment—can transform your maintenance routine. By taking proactive steps, you’ll reduce downtime, cut repair costs, and keep your operations running like clockwork.

Ready to upgrade your hydraulic cylinder pistons or need expert advice? Explore our premium hydraulic cylinder pistons or contact our team for tailored solutions. Don’t let simple mistakes derail your business—act today!

Need specialized tools for maintenance? Check out our hydraulic cylinder piston seal installation tool to ensure precise and efficient repairs.

Leave a Reply