Why Hydraulic Cylinder Piston Seals Matter

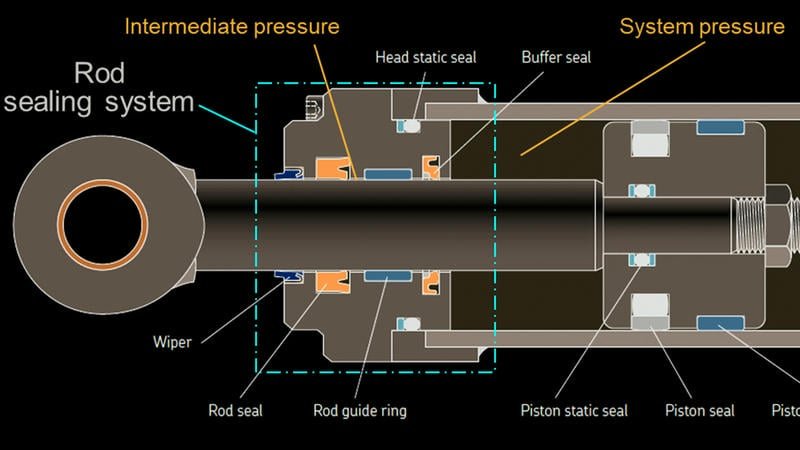

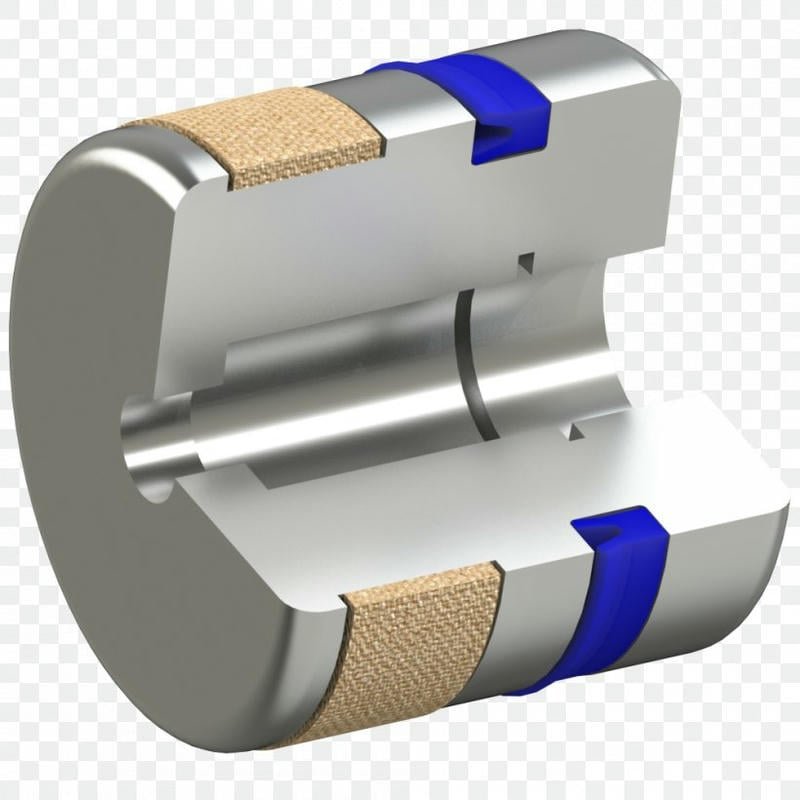

Hydraulic cylinder piston seals are the unsung heroes of hydraulic systems, tasked with preventing hydraulic fluid leaks between the piston and cylinder barrel. These seals ensure pressure is maintained on one side of the piston, enabling the hydraulic piston cylinder to generate the force needed to power heavy machinery, construction equipment, or industrial applications. According to Machine Design, piston seals are dynamic seals that endure high pressure and constant motion, making them prone to wear, contamination, or improper installation.

When a piston seal fails, it can lead to internal leaks, reduced system efficiency, increased energy costs, and even equipment breakdowns. Data shows that approximately 12.6% of hydraulic cylinder failures are linked to poor maintenance practices (Cylinders Inc.). By recognizing early warning signs, operators can act proactively to minimize downtime, avoid costly repairs, and keep equipment running safely. This article dives into five critical signs to watch for, helping you catch issues before they escalate.

5 Early Warning Signs of Hydraulic Cylinder Piston Seal Failure

Below are five key indicators operators should monitor closely. Each sign may point to a piston seal issue, and we’ll explore their characteristics, detection methods, potential causes, and actionable solutions, enriched with real-world examples and authoritative data for practical insights.

1. Cylinder Drift: The Silent Threat in Hydraulic Systems

What is it?

Cylinder drift occurs when a hydraulic cylinder moves slowly without command or under load. For example, a lifting device may gradually lower when stationary, or a mechanical arm may fail to hold its position. This suggests hydraulic fluid is bypassing the hydraulic cylinder piston seal, causing internal leakage.

How to detect it?

Observe whether the cylinder shifts position over time under load. A simple test is to place the cylinder under load, shut off the system, and check for movement. If the load drops, even by a few millimeters, drift may be present.

What does it mean?

Cylinder drift is a hallmark of piston seal failure. Internal leakage prevents the cylinder from maintaining pressure, leading to uncontrolled movement. According to Machinery Lubrication, drift is often caused by worn piston seals or scratches on the cylinder barrel.

What could cause it?

- Worn or cracked piston seals reducing sealing effectiveness.

- Scratches or corrosion on the cylinder barrel disrupting the seal’s contact surface.

- Improper seal installation, such as incorrect orientation or mismatched sizes.

- Contaminated hydraulic fluid accelerating seal material degradation.

What to do?

Inspect the piston seal and cylinder barrel immediately for wear, scratches, or corrosion. Replace damaged seals, ensuring compatibility with system pressure and temperature. If the barrel is damaged, it may need honing or replacement. Case Study: A manufacturing plant noticed drift in its press machine, causing production delays. Inspection revealed a piston seal hardened by fluid contamination. Replacing the seal and flushing the system resolved the issue.

2. Reduced Force Output: When Your Cylinder Loses Power

What is it?

Reduced force output means the hydraulic cylinder can’t generate its expected force, leading to poor task performance. For instance, an excavator may struggle to lift standard loads, or a press may produce insufficient force.

How to detect it?

Compare cylinder performance against equipment specifications or historical data. If tasks take longer or loads can’t be lifted, force output is likely reduced. A pressure test can confirm internal leakage.

What does it mean?

Reduced force output often stems from piston seal failure, allowing fluid to bypass the piston and lowering effective pressure. FPE Seals notes this can lead to decreased system efficiency and higher energy consumption.

What could cause it?

- Aging or damaged piston seals compromising sealing performance.

- Improper hydraulic fluid viscosity affecting pressure transfer.

- Pump or valve malfunctions reducing system pressure.

- Wear in internal components, such as the hydraulic cylinder piston rod.

What to do?

Check hydraulic fluid quality first, ensuring it’s free of contamination and has the correct viscosity. Next, disassemble the cylinder to inspect the piston seal and internal components. Replace worn parts and test system pressure to rule out other issues. Case Study: A construction firm found its crane had reduced force output. Inspection revealed a piston seal hardened by prolonged high-temperature operation. Replacement restored performance.

3. Slow Operation: A Red Flag for Efficiency Loss

What is it?

Slow operation occurs when a cylinder takes longer than usual to complete its extension or retraction cycle. For example, a loader’s bucket may move sluggishly, slowing down operations.

How to detect it?

Time the cylinder’s extension and retraction cycles and compare them to standard times. If cycles are noticeably longer, operation is slow. A load test can further verify performance loss.

What does it mean?

Slow operation is often caused by internal leakage, where fluid fails to fully pressurize the piston, reducing speed. RHK Hydraulics highlights worn piston seals as a common culprit.

What could cause it?

- Damaged piston seals allowing fluid bypass.

- Blockages in hydraulic lines or valves restricting flow.

- Contaminated or degraded hydraulic fluid reducing flowability.

- Reduced pump performance limiting fluid supply.

What to do?

Inspect the hydraulic system for blockages or restrictions, ensuring clear lines. Test fluid quality and replace if necessary. Disassemble the cylinder, check the piston seal, and replace worn components. Case Study: A logistics company noticed slow forklift operation. Inspection found a piston seal worn by particulate contamination. Replacing the seal and filtering the fluid restored speed.

4. Overheating: A Hidden Danger Signal

What is it?

Overheating occurs when the hydraulic cylinder or fluid reaches abnormally high temperatures during operation, exceeding normal ranges. Excessive heat can accelerate seal aging and system damage.

How to detect it?

Use an infrared thermometer or gauge to measure cylinder and fluid temperatures, comparing them to the equipment manual’s normal range. Persistent high readings indicate overheating.

What does it mean?

Overheating may result from internal leakage, which increases friction and heat generation. Quad Fluid Dynamics links overheating to worn seals or fluid issues.

What could cause it?

- Worn piston seals increasing friction between piston and barrel.

- Contaminated hydraulic fluid reducing heat dissipation.

- Cooling system failures, such as clogged radiators.

- Excessive system pressure generating additional heat.

What to do?

Check for fluid contamination or degradation and replace if needed. Ensure the cooling system is functioning, cleaning radiators or fans. Disassemble the cylinder, inspect the piston seal, and replace damaged parts. Case Study: A mining company found its hydraulic drill overheating. Inspection revealed a piston seal swollen by water-contaminated fluid. Replacing the seal and flushing the system normalized temperatures.

5. Unusual Noises: An Alarm for System Health

What is it?

Unusual noises include banging, knocking, or hissing sounds during operation, signaling potential issues in the hydraulic system. A healthy cylinder should operate smoothly and quietly.

How to detect it?

Listen carefully during equipment operation for any abnormal sounds. Cavitation (low fluid levels) or aeration (air ingress) often produces distinct noises.

What does it mean?

Unusual noises may be indirectly linked to piston seal failure. Cavitation or aeration can damage seals, leading to further leakage. Flowtech notes these issues may stem from low fluid levels or seal damage.

What could cause it?

- Cracked piston seals allowing air into the system.

- Low hydraulic fluid levels causing cavitation.

- Loose system connections introducing air.

- Degraded fluid producing bubbles.

What to do?

Check fluid levels, ensuring they’re adequate and free of bubbles. Inspect system connections and tighten loose fittings. Disassemble the cylinder, check the piston seal, and replace damaged parts. Case Study: An agricultural firm heard knocking in its tractor’s hydraulic system. Inspection found a cracked piston seal allowing air ingress. Replacing the seal and topping up fluid eliminated the noise.

Practical Tips to Prevent Piston Seal Failure

To avoid piston seal failure, operators and maintenance teams can implement these strategies:

- Regular Inspections: Check cylinders weekly for leaks, drift, or noises. Use the Cylinders Inc. maintenance checklist for comprehensive coverage.

- Fluid Management: Test hydraulic fluid regularly for contamination, water, or viscosity changes. Replace fluid annually and flush the system.

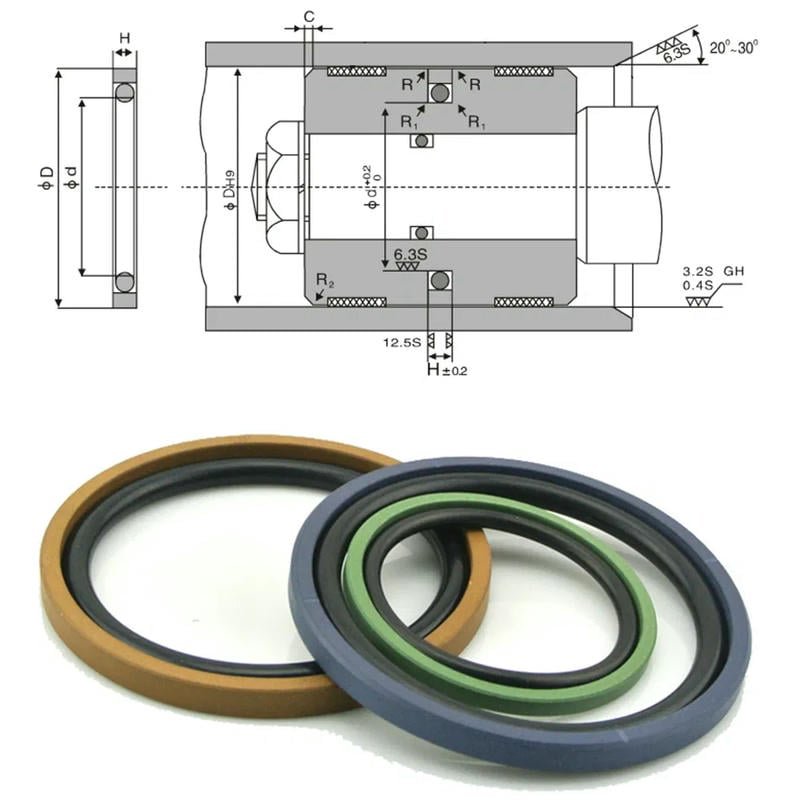

- Proper Installation: Ensure piston seals are installed correctly using hydraulic cylinder piston seal installation tools and manufacturer guidelines. Refer to Allegheny York for installation best practices to avoid orientation errors or damage.

- Training and Documentation: Train operators on hydraulic system maintenance and log all inspections and repairs to track issue patterns.

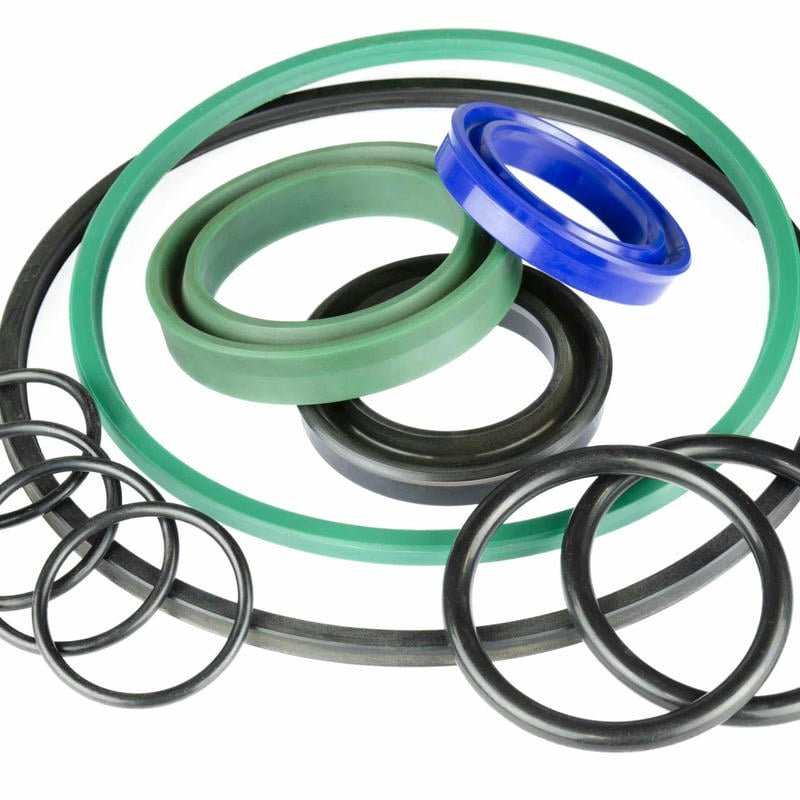

- High-Quality Seals: Select seals compatible with system pressure, temperature, and fluid, such as polyurethane or PTFE (Trelleborg).

Proactive Maintenance for Longevity

Hydraulic cylinder piston seal failure can lead to production halts, soaring costs, and safety risks. By staying vigilant for cylinder drift, reduced force output, slow operation, overheating, and unusual noises, operators can catch issues early and act decisively. Regular maintenance, quality seals, and proper installation are the cornerstones of a reliable hydraulic system.

Our experience shows proactive maintenance can reduce cylinder failure rates to below 10% (Cylinders Inc.). Whether you’re an operator or maintenance engineer, understanding these signs and taking preventive steps can significantly extend equipment life and optimize performance.

Call to Action: Inspect your hydraulic system today for these warning signs. If you need high-quality hydraulic cylinder parts or expert hydraulic cylinder repair services, visit our website for tailored solutions to keep your equipment running smoothly.

Leave a Reply