Imagine your production line grinding to a halt because of a hydraulic leak. Frustrating, right? According to a 2025 industry report, 68% of hydraulic leaks stem from hydraulic cylinder piston seal failure (Fluid Power Journal). These leaks don’t just cause downtime—they rack up repair costs and can even pose safety risks. But here’s the good news: with the right knowledge and quality seals, you can prevent these issues. In this article, we’ll explore why piston seals fail, how to choose the best ones, and practical maintenance tips to keep your systems leak-free. Let’s dive in!

Understanding Hydraulic Cylinder Piston Seals

Hydraulic cylinder piston seals are the unsung heroes of hydraulic systems. They sit snugly between the piston and cylinder wall, preventing hydraulic fluid from leaking while maintaining pressure for smooth operation. Think of them like the gasket in your car engine—small but critical.

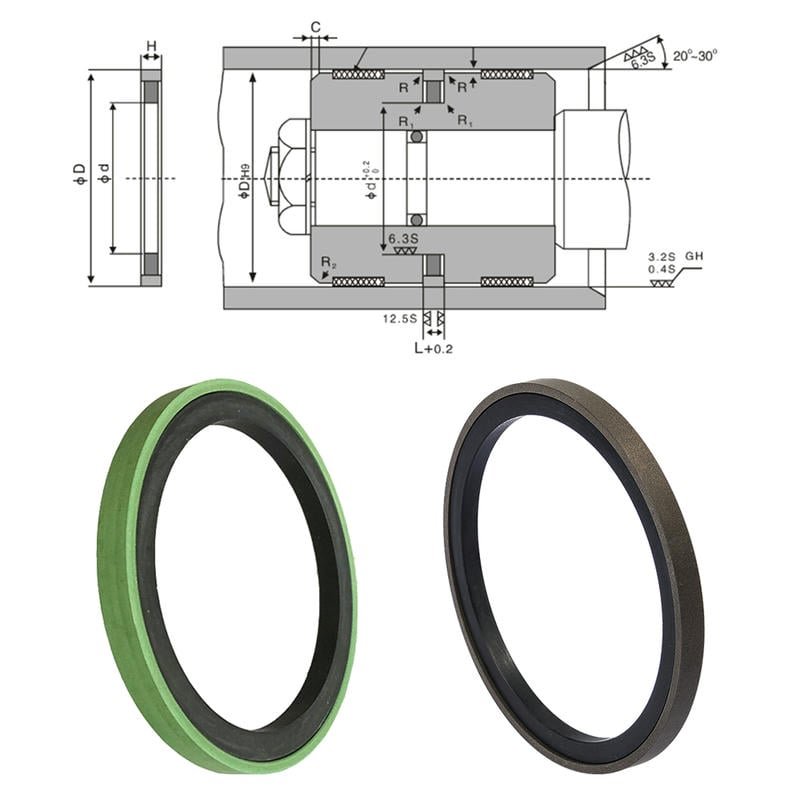

Seals come in various types, each suited for specific conditions:

- O-Rings: Affordable and great for low-pressure systems.

- U-Cup Seals: Ideal for higher pressures, offering better sealing.

- Composite Seals: Combine materials like PTFE and rubber for heavy-duty applications.

Choosing the wrong seal can lead to leaks, so understanding your system’s needs is key. For instance, a seal for a high-pressure construction excavator needs to be tougher than one for a low-pressure assembly line.

Common Causes of Hydraulic Cylinder Piston Seal Failure

Why do seals fail? Let’s break down the top culprits, backed by data from Machinery Lubrication:

- Improper Installation: A 2024 study found 45% of seal failures result from incorrect installation, like misalignment or over-compression.

- Wear and Tear: Constant friction wears seals down, especially in high-cycle systems.

- Contamination: Dirt or debris in the fluid can scratch or degrade seals, causing leaks.

- Incompatible Materials: Using seals not suited for your hydraulic fluid can lead to swelling or cracking.

- Excessive Pressure or Temperature: Operating beyond a seal’s limits causes extrusion or hardening.

These issues aren’t just annoying—they’re costly. A single leak in a hydraulic cylinder and piston can lead to thousands in downtime and repairs, as we’ll see in a real-world example below.

How to Choose the Right Hydraulic Cylinder Piston Seals

Selecting the right hydraulic cylinder pistons and seals is like picking the perfect pair of shoes: fit and function matter. Here’s what to consider:

- Pressure Rating: Ensure the seal can handle your system’s maximum pressure (e.g., U-cups for pressures above 10 MPa).

- Temperature Range: Polyurethane seals work well from -40°C to 120°C, while PTFE handles extreme heat.

- Fluid Compatibility: Check if the seal material (e.g., nitrile rubber) is compatible with your hydraulic fluid.

- Application Type: Dynamic seals for moving pistons need higher durability than static ones.

Pro tip: Always source seals from reputable suppliers. Our seals, for example, undergo rigorous testing to meet ISO 9001 standards, ensuring reliability.

Maintenance Tips for Hydraulic Cylinder Piston Seals

Prevention is better than a costly repair. Here are five maintenance tips for hydraulic piston cylinder seals to keep leaks at bay:

- Regular Inspections: Check seals monthly for wear, cracks, or leaks.

- Proper Installation: Use dedicated tools like our hydraulic cylinder piston seal installation tool to avoid damaging seals during installation.

- Clean Fluid: Use filters to keep hydraulic fluid free of contaminants.

- Lubrication: Apply compatible grease to reduce friction during installation.

- Monitor Conditions: Stay within pressure and temperature limits to avoid seal stress.

A 2023 report by Power & Motion found that regular maintenance can extend seal life by up to 40%, saving thousands in hydraulic cylinder repair costs.

Case Study: Slashing Downtime with Quality Seals

Meet Sarah, a maintenance manager at a Midwest manufacturing plant. Her team faced frequent hydraulic leaks, costing $10,000 monthly in downtime. After switching to our high-quality hydraulic cylinder parts and implementing a monthly inspection routine, leaks dropped by 60% in just three months. “These seals are a game-changer,” Sarah said. “Our production line is back on track, and we’re saving big.”

Another client, a construction firm in Texas, reported similar success. By upgrading to composite seals for their hydraulic cylinders, they reduced maintenance costs by 25% annually.

Expert Advice: Seal the Deal with Quality

Leaky hydraulic systems are a headache, but they don’t have to be. By understanding why hydraulic cylinder piston rod seals fail, choosing the right ones, and maintaining them properly, you can keep your operations running smoothly. Don’t let a tiny seal bring your business to a halt—invest in quality today.

Ready to upgrade your seals? Contact us for expert advice and top-tier hydraulic cylinder piston seals. Have a question about seal maintenance? Drop it in the comments below—we’d love to hear from you!

Leave a Reply