Picture this: you’re in the middle of a critical job, and your hydraulic system starts acting up. You touch the hydraulic piston cylinder, and it’s scorching hot, with performance tanking fast. If you don’t act quickly, you’re looking at costly repairs or even a full system shutdown. Don’t panic! This article dives into why your hydraulic piston cylinder is overheating and gives you a straightforward four-step plan to fix it, so you can get back to work with confidence.

Why Hydraulic Piston Cylinder Overheating Is a Big Deal

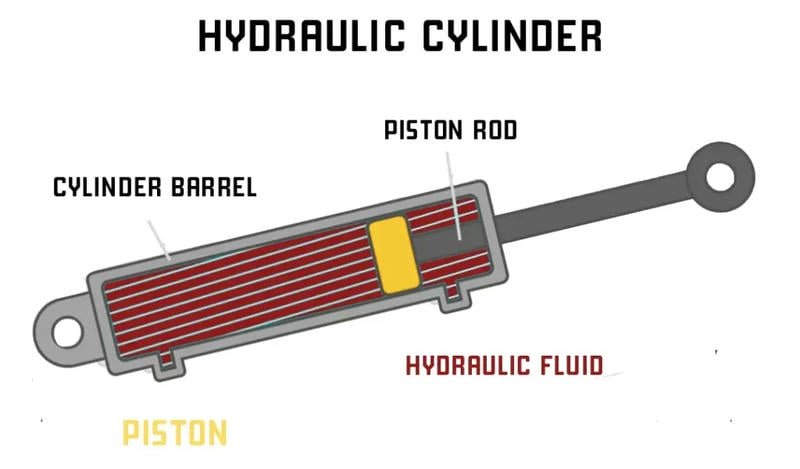

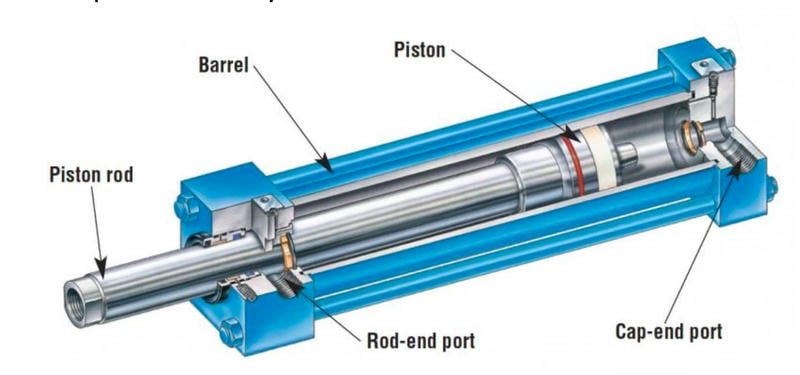

Hydraulic cylinder and piston are the heart of many industrial applications, from manufacturing lines to construction equipment. They rely on hydraulic fluid to transfer power and drive motion. But when fluid temperatures climb above 180°F (82°C), overheating sets in, bringing a host of problems:

- Reduced Efficiency: High temperatures thin out hydraulic fluid, weakening lubrication and increasing friction.

- Component Damage: Overheating accelerates wear on seals, O-rings, and other parts, leading to leaks.

- System Failure: Persistent overheating can cause catastrophic breakdowns, halting operations and racking up repair bills.

According to Machinery Lubrication, overheating is the second most common cause of hydraulic system failures, right behind leaks. Tackling it promptly saves your equipment and your bottom line.

Common Causes of Hydraulic Piston Cylinder Overheating

To fix overheating, you first need to know what’s causing it. Here are the top five culprits behind hydraulic piston cylinder overheating:

- Contaminated Hydraulic Fluid: Dirt, debris, or water in the fluid can clog passages, increasing friction and heat.

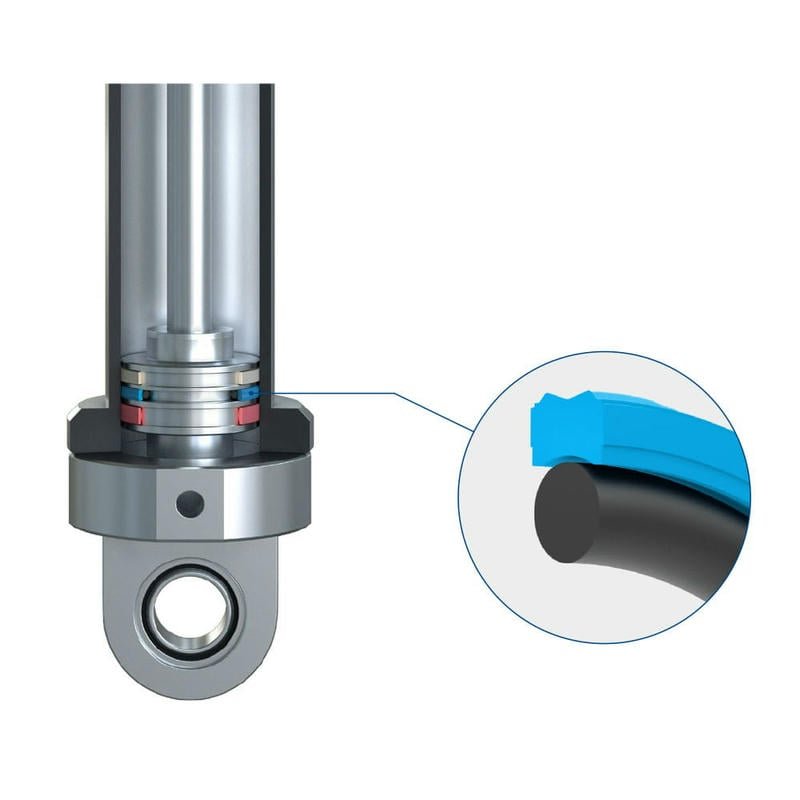

- Internal Leaks: Worn hydraulic cylinder piston seal can let fluid bypass the piston, lowering efficiency and generating heat.

- Excessive Friction: Misaligned cylinders or inadequate lubrication cause components to rub, producing heat.

- Incorrect System Settings: Improper pressure or flow settings can overwork the system, driving up temperatures.

- Inadequate Cooling: Clogged heat exchangers or low fluid levels can prevent the system from dissipating heat.

Pinpointing these issues sets the stage for effective troubleshooting.

How to Diagnose Hydraulic Piston Cylinder Overheating

Before jumping into fixes, confirm overheating is the issue with your hydraulic cylinder. Look for these telltale signs:

- High Fluid Temperature: Use a thermometer to check hydraulic fluid temperature. Anything above 180°F (82°C) signals trouble.

- Sluggish Performance: If the cylinder’s extension or retraction is slow or jerky, overheating could be to blame.

- Unusual Noises: Grinding or high-pitched sounds may indicate increased friction.

- Visible Damage: Check for fluid leaks or worn seals around the cylinder.

These checks help you confirm overheating and prepare for the next steps.

4 Steps to Fix Hydraulic Piston Cylinder Overheating

Follow these four practical steps to diagnose and resolve overheating, getting your system back to peak performance:

Step 1: Check and Maintain Hydraulic Fluid Quality

Hydraulic fluid is the lifeblood of your system, and contaminated or degraded fluid is a leading cause of overheating.

- Inspect Fluid Levels: Ensure the fluid is at the recommended level. Low levels force the pump to work harder, generating heat.

- Assess Fluid Condition: Look for discoloration or milky fluid (indicating water contamination). Contaminants like dirt, water, or metal particles can cause issues.

- Verify Viscosity: Confirm you’re using the right fluid type and viscosity for your system. Incorrect viscosity affects cooling and lubrication.

- Replace Fluid: If the fluid is contaminated or past its service life, replace it with fresh, clean hydraulic fluid.

Hydraulic Cylinders, Inc. recommends regular fluid changes to significantly reduce overheating risks.

Step 2: Inspect Seals and Components for Leaks

Internal leaks reduce system efficiency and generate heat.

- Check Piston Seals: Look for wear, cracks, or damage on hydraulic cylinder piston seals. Replace as needed.

- Look for External Leaks: Inspect around the cylinder for fluid seepage, which may indicate seal or component failure.

- Replace Faulty Parts: Ensure all components are in good working order, swapping out damaged ones promptly.

Seal failure is a top contributor to overheating, and timely replacement prevents further damage, per Fluid Power Journal.

Step 3: Ensure Proper Alignment and Lubrication

Misalignment and poor lubrication lead to excessive friction and heat buildup in the hydraulic cylinder piston rod.

- Verify Alignment: Ensure the cylinder is properly aligned with the load to prevent binding or uneven wear.

- Lubricate Moving Parts: Apply recommended lubricants to the cylinder rod and other moving components to minimize friction.

- Inspect for Wear: Check the cylinder rod and inner walls for scratches or wear, which may signal alignment issues or insufficient lubrication.

Proper lubrication and alignment are critical for extending cylinder life, according to Cylinders, Inc.

Step 4: Verify System Settings and Cooling Mechanisms

Incorrect settings or cooling failures can drive overheating.

- Check Pressure Settings: Ensure system pressure aligns with manufacturer specifications. Excessive pressure creates unnecessary heat.

- Inspect Flow Rates: Confirm flow matches the cylinder and application needs.

- Examine Cooling Systems: If your system includes heat exchangers or other cooling devices, ensure they’re clean, unclogged, and functioning properly.

Efficient cooling is vital for maintaining stable fluid temperatures, as noted by Hydraulic Power Sales.

Prevention Beats Repair

Hydraulic piston cylinder overheating is a serious issue, but it’s one you can tackle with the right approach. By understanding the causes and following a systematic diagnosis and repair process, you can avoid costly downtime and extend your equipment’s lifespan. Regular maintenance—checking fluid quality, seals, alignment, and system settings—is the key to keeping your hydraulic system running smoothly.

Want to learn more about hydraulic cylinder care or need hydraulic cylinder repair? Visit our website for top-quality hydraulic piston cylinders and expert advice. Take action now to keep your equipment in top shape!

Recommended Maintenance Schedule

Here’s a suggested maintenance schedule to prevent overheating of your hydraulic cylinders:

| Frequency | Task |

|---|---|

| Daily | Check hydraulic fluid levels |

| Weekly | Lubricate cylinder rods and pivot points |

| Monthly | Inspect fluid quality, replace if needed |

| Quarterly | Conduct fluid analysis, replace hydraulic fluid filters |

| Annually | Perform system flush and fluid replacement |

Sticking to these practices can drastically reduce overheating risks and enhance system reliability.

Leave a Reply